Rocket Studies

Over the past few days, we have been working on rockets: building them, launching them, and designing and executing an in-depth test of design parameters. Through this process, the ultimate goal is to determine an optimization of the design parameters in search of the best rocket that can be built.

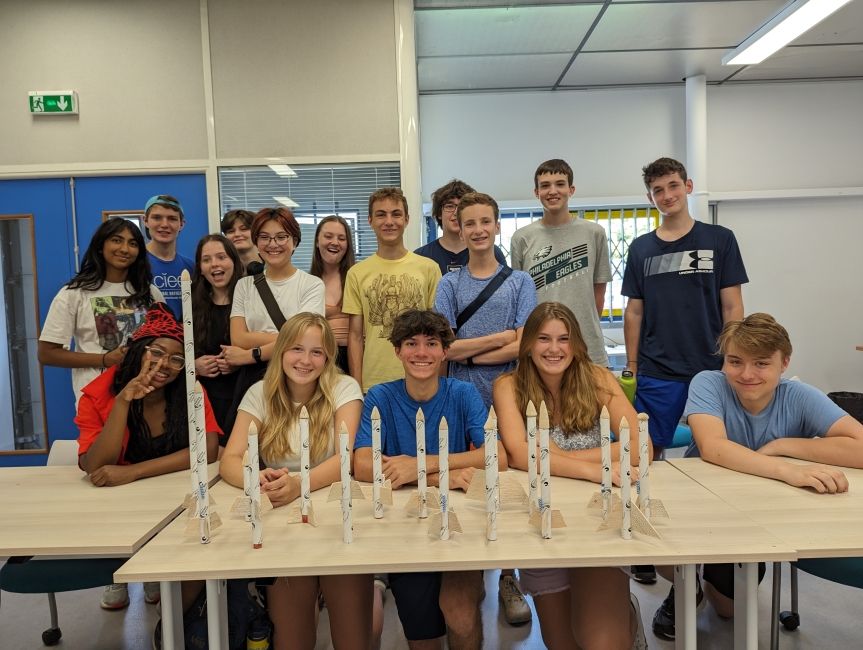

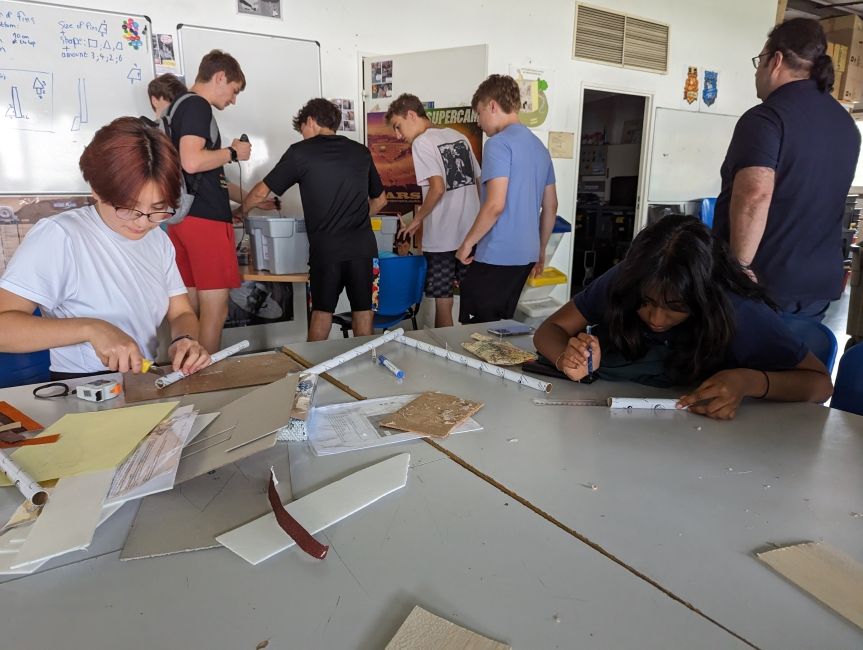

Our endeavors began with an open build time, where the students were able to build a rocket with complete freedom, in what they thought would work the best, but without any specific rationale behind it, aside from their intuition. They had a variety of materials, from tubes for the body, sheets of balsa wood for the fins, and blocks of balsa to shape into the nose cones. Most rockets were pretty similar, but there were a few rather unique designs.

Once the design and construction concluded, we got to launch the rockets! After traveling to a nearby park and setting up our launch pads, one by one, we tested them. It was fun to watch them launch, some with more success than others. Some of the rockets flew very high, whereas others were less successful, shall we say. A few had challenges with the parachute system, so recovery was not always possible, but all of them certainly provided entertainment!

At our next rocket workshop, the students reflected on their launches, and brainstormed ideas of design parameters that potentially could have had an impact on the flight performance. After coming up with a full list, they then broke each one of those down and identified values of that parameter to test. For example, when thinking about the length of the tube for the body, they decided to test 14 cm, 24 cm, 34 cm, and 60 cm. Once all of the variations were made, it was production time! The students split up into different roles and began making all 18 different rockets to test. As production progressed, Xander wanted to be sure that I would let everyone reading this blog know that his rockets were the best, so I feel obliged to mention that!

Our following workshop saw the completion of production, followed by an afternoon of launching. While launching, three different measurement stations were set up to calculate the angles of the rockets at their flight peak, thus allowing for triangulation of the height that the rocket flew. The tests had mixed results, as some performed great, and some had some quality control issues, especially with the parachute system. Flight heights were also a mixed bag, as a number of rockets failed to maintain a vertical trajectory, which with rockets, is generally a bad thing!

Going forward, our next steps will be some significant analysis of the test results, both in calculating the maximum height that each rocket reached as well as determining the impact each design parameter had on the outcome. Once we have identified the optimal values for each parameter, the perfect rocket can be made! I'm looking forward to seeing how well that rocket flies!

Related Posts

Au revoir Toulouse!

This morning, Session II Aerospace Engineering students departed with hearts overflowing with joy and memories to treasure for a lifetime! As the sun rose, the excitement in the air was... keep reading

Exploring Aerospace Engineering in Toulouse, France

Toulouse, France is often called the aerospace capital or “Space City” of Europe, and for good reason. Home to major aerospace companies like Airbus and renowned research institutions, this city... keep reading

Akrobranch in the Pyrénées

Toe-tapping on wires 40 feet above thundering waterfalls in the foothills of the Pyrénées mountains... music to the ears of the CIEE Aerospace Engineering crew! This past weekend the students... keep reading